High Temperature CIP Collector

A0-00249

HIGH TEMPERATURE CLEAN-IN-PLACE

Protect the purity of your beverage through Wild Goose Canning’s new high temperature sanitation feature. Wild Goose gives you peace of mind that your CIP process is safe and effective.

BENEFITS

- Allows thorough sanitation up to 180°F (82°C), above temperatures proven to eliminate even the most heat-resistant organisms

- Minimizes potential cross-contamination when transitioning between multiple yeast strains and beverage types

- Reduces the time needed to reach desired sanitation levels

- Protects operator safety

- Maintains long-term component integrity

FEATURES

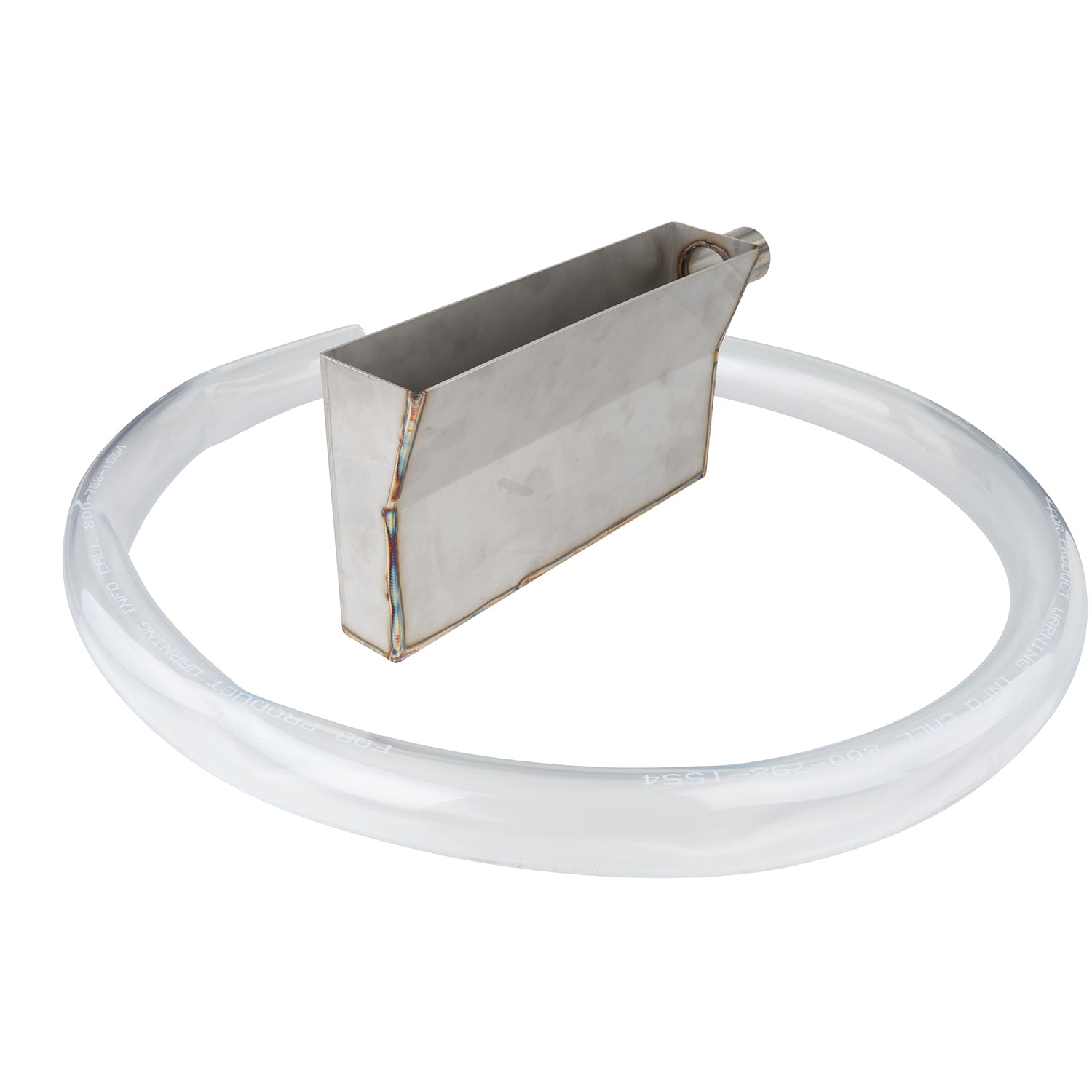

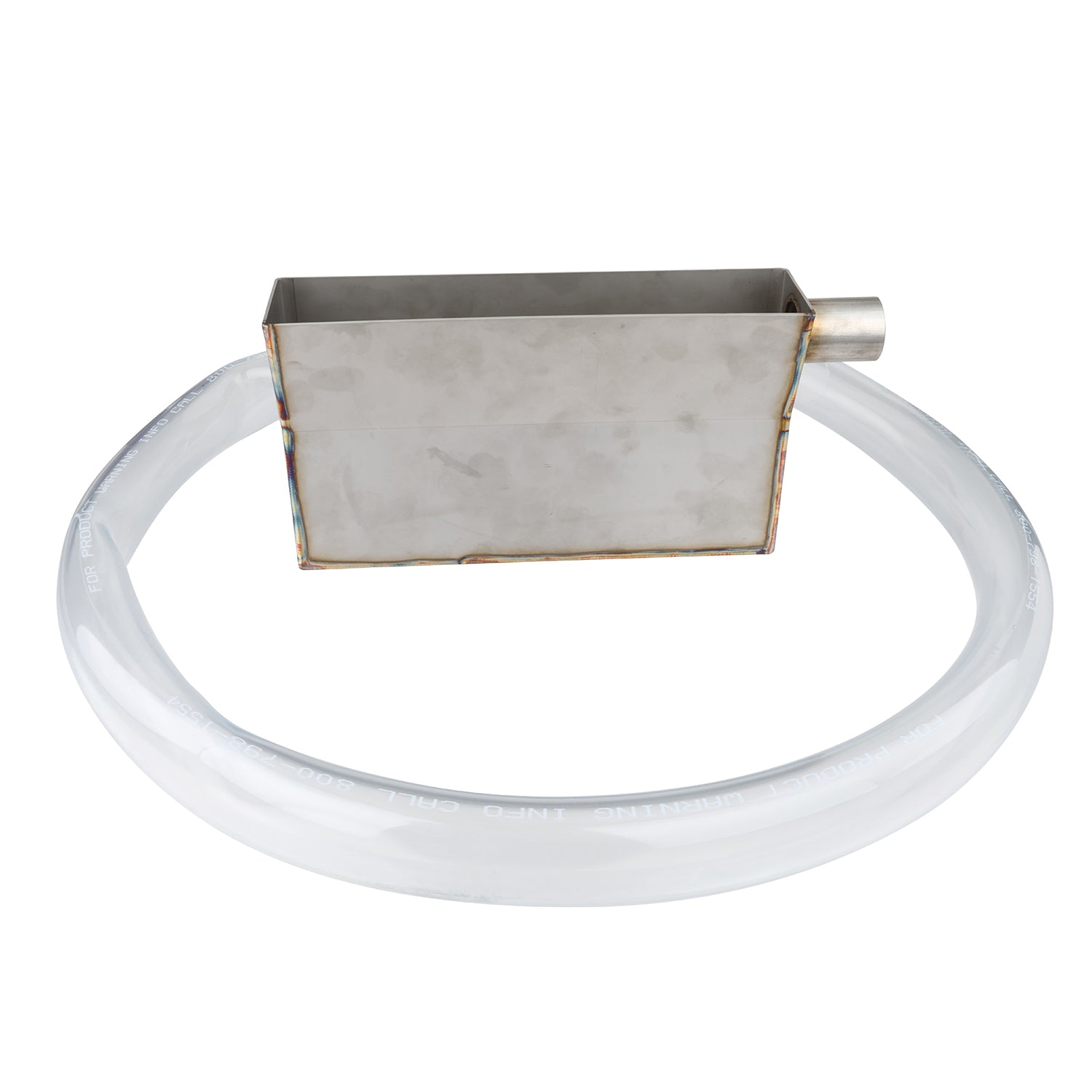

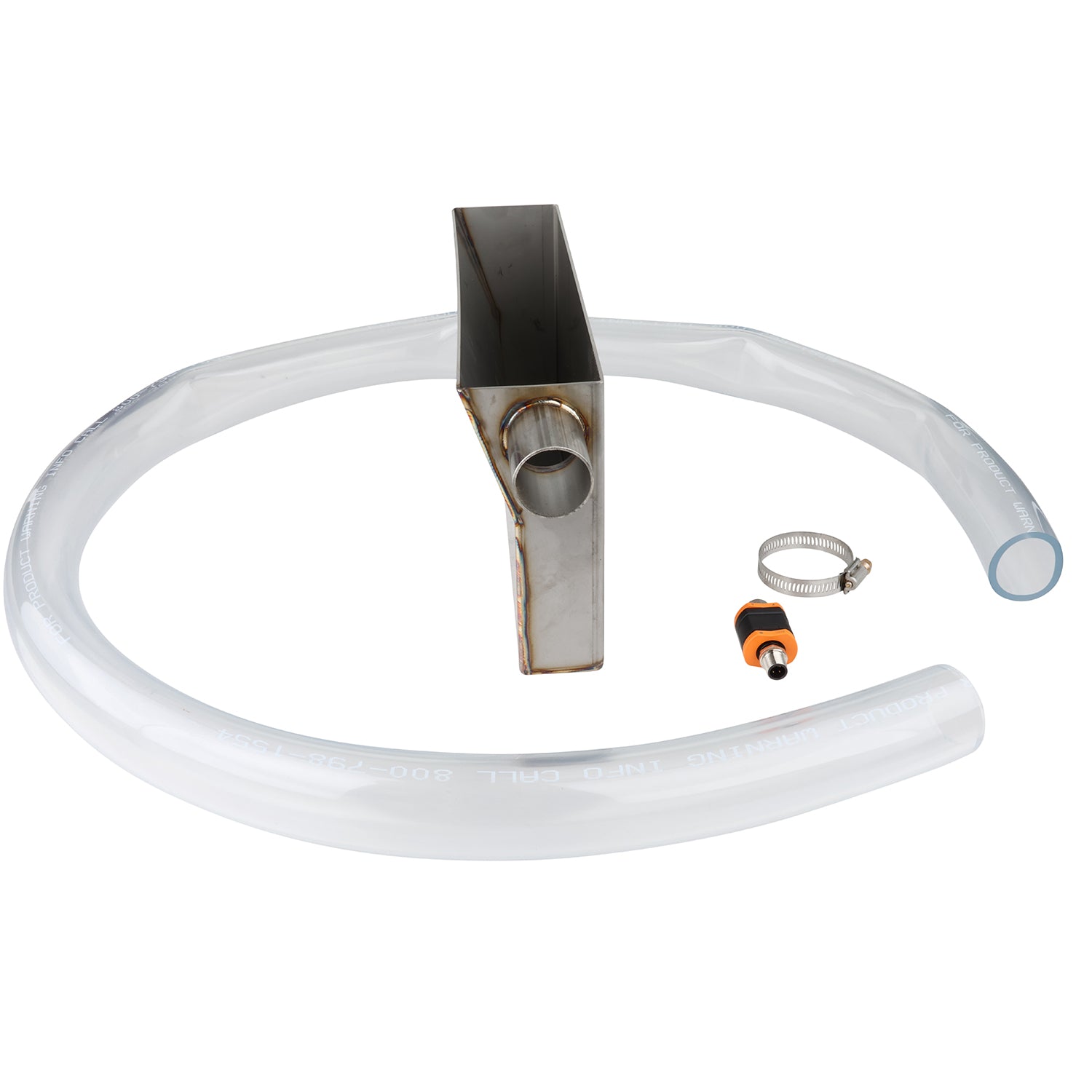

- TROUGH GUARD

Within the CIP trough, fill heads are submerged in high temperature cleaning liquid. The trough collects and routes hot liquid away to eliminate potential splash on the operator and reduce prolonged high temperature fluid contact with the conveyor.

- SOFTWARE SAFEGUARDS

Software safeguards ensure operator safety. The computer locks all fill heads into an open, lowered position until the CIP process is completed and temperature is reduced.

- TEMPERATURE MONITOR

Incoming CIP liquid temperature and pressure are monitored in real-time through the Inlet Sensors.

AVAILABILITY

- EXISTING SYSTEMS

- Available for purchase and retrofit compatible with all existing standard, mobile or CE-certified Wild Goose Canning Evolution Series, WGC-100 and WGC-250 systems. Must be utilizing Inlet Pressure & Temperature Monitors accessory.

- Installation: 15-25 minutes for most customers. Remote software updates implemented via call with Wild Goose Customer Service. Customer self-installation of trough during CIP process.

- Not compatible with Gosling, Fusion or WG8/10 systems.

BEST PRACTICES

FOR HIGH TEMPERATURE CLEANING OF YOUR MACHINE

- Follow all suggested preventative machine maintenance schedules.

- Visually inspect tubes and fittings for any sign of wear or cracking before utilizing High Temperature CIP features.